For those tackling outdoor DIY projects, Concrete mix can be a great ally. With it, you can guarantee a sturdy foundation for your fence posts in no time! Knowing the right usage and having the appropriate tools will help you make sure that your posts have a strong, lasting hold.

For successful installation of a fence, a specialised blend of water, cement, admixtures and aggregate, otherwise known as concrete mix, is essential. The required mix size and strength will depend on the size and type of fence post that needs to be secured, as the concrete must provide adequate support that can withstand weight and pressure. Plus, it is possible to tailor the mix to fit any size or type of available fence posts.

A typical concrete blend delivers the power needed to anchor wooden fence posts securely. The concoction contains one part cement, two parts aggregate, and a dash of admixture for enhanced fortification. Although the ratio of cement to aggregate can be modified to create stiffer or more pliable bases, the typical balance gives fence posts just enough strength to stay upright.

Metal fence posts require a formidable cement mixture to give them the strength and longevity to not chip or crack. Concocting this particular blend is done with one part cement and one part aggregate, plus a generous portion of admixture to get the desired durability. This specialization allows for metal posts to stand tall while retaining their needful strength.

It is crucial to have the correct amount of water when preparing concrete, as an excessive amount can compromise the mix’s solidity. On the other hand, if too little water is added it can be hard to manage. Additionally, when combining all the ingredients, it is crucial to thoroughly mix them together as any scattered material can result in fragile spots.

Before being poured into its forms, concrete must be adequately prepped. This entails laying down a layer of gravel, assuring the area is sufficiently leveled, and certifying the forms are correctly sized and securely secured. If the forms are overly voluminous, the pressure from the concrete might cause them to buckle or collapse during the pouring process.

After the framing is done, the next step is to fill the form with concrete. It requires utmost attention and control to make sure all the spaces are completely filled and that it forms a flat, even surface. After all that effort, it must then be allowed to dry fully – the amount of time this can take is contingent on the post dimension, ranging from a few hours to a couple days at most.

With the concrete fully dried, installing the fence post is the next step. Bolted-down firmly, the screws must be tightened to guarantee stability. Once this crucial process is done, the post is primed for it’s destined purpose.

For outdoor DIY-ers wanting secure, durable fence posts, having the right concrete mix is a critical step. Proper mixing and preparation will give you a reliable base that will last long into the future. In almost no time at all, your fence post foundation will be set and secure!

The construction of a fence post requires the infusion of a specific mix of materials. This complex mixture consists of cement, water, sand, and aggregate; these components ensure strength and durability in the foundation. Getting the ratio of each ingredient right is important in order to guarantee the longevity and sturdiness of the post.

To erect a sturdy, secure post, you will need a blend of four elements: cement, water, sand, and aggregate. In most cases, combining one volume of cement, two volumes of sand and four volumes of aggregate will yield a satisfactory result for an average-sized post. However, these components may need to be proportioned differently depending on the type and size of the post being constructed.

The first portion of this process requires combining the cement and water together in a large vessel. The key to a perfect consistency is to slowly incorporate the water into the mix, exercising caution if you find yourself tempted to add an excessive amount. Afterwards add the sand and aggregate, stirring until every ingredient is seamlessly incorporated. This will ensure a uniform concrete mix is created.

Once the concrete is ready to go, it’s time to set up the fence post. Start by making sure the area is flat, even, and all cleared of obstructions. Position the post securely in the earth, and be sure it is upright and aligned to perfection. Then, carefully pour in the mixture of concrete to surround your post – ensure that it is evenly distributed for a beautifully polished finish.

After the concrete blend has been allowed to settle for 24 hours, a layer of gravel should be distributed about the post. Not only will this guarantee that the post remains secure in its position, but it will also act as a basin for drainage, as well as provide a solid base and minimize any possibility of the post slipping out of place.

The concrete post must be closely monitored and secure so ensure the fence remains sturdy. Regularly inspect the post for weakened structures such as cracks in the mix. Additionally, make sure that the post is securely sunken into the ground; if not steady, it can move or be limp from lack of reinforcement resulting in a weak fence line.

Every fence post needs a sturdy and durable base to ensure that it can remain standing for years to come. The right concoction of concrete mix is crucial to achieving this goal; from calculating the proper ratios of ingredients to properly maintaining the post, you must take the necessary steps. When done correctly, you can rest assured that your fence post will remain reliably secure in its place.

Related Product

Nail Stake

Product information: Description Unit Pallet Weight(kg) 3/4″x12″ 10pcs/box 150boxes/pallet 0.6200 3/4″x18″ 10pcs/box 100boxes/pallet 0.9250 3/4″x24 […]

T Post

Material: rail steel Weight: 0.85,0.95,1.25,1.33lbs/ft etc Length: 5′-10′ etc Surface: painted with spade,painted no spade,unpainted with spade,unpainted without spade,hot-dipped g […]

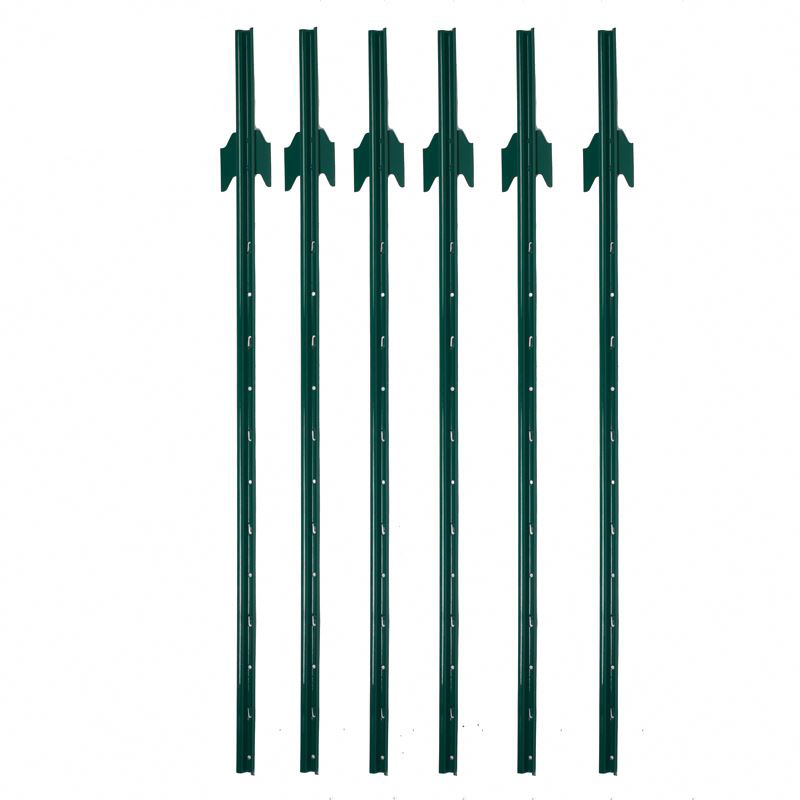

Studded T Post

material: rail steel weight: 0.85,0.95,1.25,1.33lbs/ft etc length: 5′-10′ etc surface: painted with spade,painted no spade,unpainted with spade,unpainted without spade,hot-dipped g […]

T Post Clip

These heavy duty T-post clips fit standard size 1.25 and 1.33 lb. studded T-posts. Manufactured from 11-1/2 gauge wire that is Hot-dipped galvanized, these clips are designed for f […]

Israel Y Post

Y post with teeth provides the most reliable way of fencing wire attachment by threading the wire through the holds along the post, gripping the wire with is specially designed tee […]

U Post

Heavy Duty Garden U Shaped Steel Fence Post With Spade Shape: U shape, with or without spade Material: low carbon steel, rail steel, etc. Surface: Powder coated Advantage: Easily A […]

Y Post

Length:1.35m,1.5m,1.65m,1.8m,2.4m etc Weight:1.58kgs,1.86kgs,1.9kgs,2.04kgs/m etc Surface:painted, Hot dip galvanized, No paint Usage:farm fencing,garden fencing Packing:400pcs/pal […]

Y Post Cap

Y Posts Caps is also called safety cap or Star picket caps. It used for Y star picket . It can cover sharp edges of Y posts. Type Size(L x W X H) Thickness Weight Round 57x57x60mm […]

Post time: 2023-08-16